In modern power distribution systems, ABC cable (Aerial Bundled Cable) has become a preferred solution for utilities, EPC contractors, and infrastructure developers seeking safer, more reliable overhead lines. Unlike traditional bare conductors, ABC cable integrates multiple insulated aluminum conductors into a single bundled assembly, significantly reducing electrical hazards and improving system performance.

As a global manufacturer of overhead conductors and power cables, HNBF Power supplies ABC cable solutions designed to meet international utility standards and demanding environmental conditions.

What Is an ABC Cable?

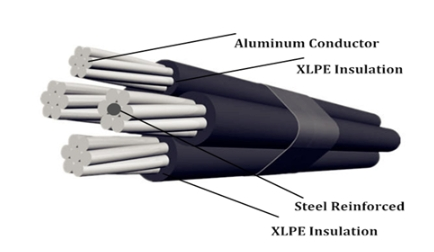

ABC cable is an overhead power distribution cable consisting of insulated phase conductors, a neutral conductor (often messenger-supported), and sometimes a street-lighting conductor. The conductors are twisted or bundled together, forming a compact and mechanically stable configuration.

Key Construction Features

-

Aluminum phase conductors with XLPE insulation

-

Bare or insulated neutral messenger conductor

-

UV-resistant and weatherproof outer insulation

-

Compact bundle design for overhead installation

This construction minimizes the risk of phase-to-phase faults and accidental contact, making ABC cable ideal for densely populated and challenging terrains.

Engineering Advantages of ABC Cable

From an engineering and procurement perspective, ABC cable offers several measurable benefits:

Enhanced Safety

Fully insulated conductors reduce the risk of electrocution, short circuits, and fire hazards. This is especially critical in urban, rural, and forested areas.

Improved Reliability

ABC cable performs well in adverse weather conditions such as high winds, heavy rain, and ice loading. Reduced conductor clashing leads to fewer outages.

Lower Power Losses

Optimized conductor spacing and insulation help minimize technical losses compared to traditional bare overhead lines.

Reduced Maintenance Costs

With fewer faults and less exposure to environmental damage, utilities experience lower long-term maintenance and outage management costs.

Applications of ABC Cable

ABC cable is widely used across multiple power distribution scenarios:

Urban and Residential Networks

Ideal for congested areas where safety, aesthetics, and right-of-way constraints are critical.

Rural Electrification Projects

ABC cable enables faster and safer network expansion with reduced line losses and improved service continuity.

Industrial and Commercial Distribution

Factories, warehouses, and commercial zones benefit from reliable overhead distribution without complex underground installations.

Temporary and Special Installations

Construction sites and infrastructure expansion projects often rely on ABC cable for rapid deployment.

ABC Cable vs Traditional Bare Conductors

When compared to AAC, AAAC, or ACSR bare conductors, ABC cable offers a different value proposition:

| Aspect | ABC Cable | Bare Conductors |

|---|---|---|

| Safety | High (insulated) | Low to moderate |

| Installation | Simple and compact | Requires larger clearances |

| Fault Rate | Low | Higher |

| Maintenance | Minimal | Frequent inspections |

| Initial Cost | Moderate | Lower |

| Lifecycle Cost | Lower overall | Higher long-term |

For utilities focused on long-term performance and safety compliance, ABC cable often proves to be the more economical choice over its lifecycle.

Manufacturing Quality and Standards

At HNBF Power, ABC cable manufacturing follows strict quality control processes. Conductor stranding, insulation extrusion, and final testing are performed in accordance with recognized international standards. Each production stage is monitored to ensure:

-

Consistent conductor conductivity

-

Uniform insulation thickness

-

High mechanical strength

-

Resistance to UV, moisture, and thermal aging

This ensures that every ABC cable supplied meets the technical expectations of engineers and procurement teams worldwide.

Procurement Considerations for ABC Cable

When sourcing ABC cable, buyers should evaluate:

-

Voltage rating and conductor size

-

Insulation material and thickness

-

Compliance with utility or project standards

-

Supplier manufacturing capability and testing infrastructure

-

Long-term supply consistency

Working with an experienced manufacturer like HNBF Power helps reduce procurement risk and ensures technical alignment with project specifications.

FAQs About ABC Cable

1. What voltage levels are ABC cables typically used for?

ABC cables are commonly used in low-voltage and medium-voltage distribution networks, depending on design and insulation rating.

2. Is ABC cable suitable for coastal or high-humidity environments?

Yes. With proper insulation and corrosion-resistant aluminum conductors, ABC cable performs well in humid and coastal conditions.

3. Can ABC cable replace existing bare conductor lines?

In many cases, yes. ABC cable is often used in network upgrades to improve safety and reduce outages without major structural changes.

4. How long is the service life of an ABC cable?

When manufactured and installed correctly, ABC cable can offer a service life of 25–30 years or more.

5. Does ABC cable require special installation tools?

Installation is generally straightforward and may require standard overhead line hardware with minor adaptations.

Conclusion

ABC cable plays a critical role in modernizing power distribution networks by improving safety, reliability, and operational efficiency. For utilities and EPC contractors focused on long-term performance and regulatory compliance, it represents a smart engineering choice.

If you are planning a power distribution project or upgrading existing overhead lines, contact HNBF Power to discuss customized ABC cable solutions tailored to your technical specifications and procurement requirements. Our engineering and manufacturing expertise ensures dependable performance from design to delivery.